|

| I just cleaned my machine a week ago, so it's actually not TOO bad, but I still like the shiny AFTER picture! |

I have a confession to make…technically, my first love is MOVIES! I know, totally NOT craft related. I’m a multi-faceted person, what can I say! ;)

Well, since we’re being all honest now, the first machine I ever "threaded" with a 35 mm Christie film projector.

When I went to clean out my sewing machine, I had absolutely no idea what I was doing. But then, I had this “AH HAH” moment. Having worked as a manager at a local movie theater for the past 12 years, I couldn’t help but see the remarkable similarities between a projector (yes, film is DUSTY!) and my sewing machine. It was probably just me having a moment of nostalgia since nowadays, in this digital-age of film, 35 mm projectors are few and far between. Hey, they both get threaded, so they’re practically the same thing, right?

|

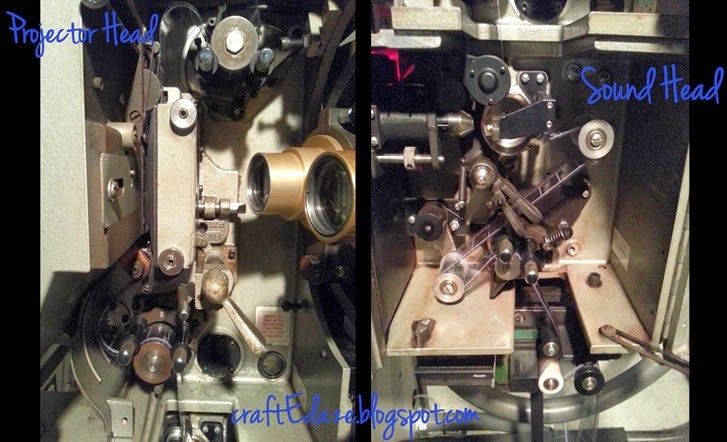

| 35 mm Projector |

Believe it or not, much like my Brother, a 35 mm projector has a thread track that the film passes through where dust would collect (albeit, more intimidating than my pretty, quaint little sewing machine). Have you ever seen a movie with those horrible white or green lines running through it? Yep, that was most likely cause by an improperly cleaned projector. Much like a projector, an improperly cleaned sewing machine can make for yucky sewing.

How did we clean those ridiculously expensive, intricate projectors?? Well, at the end of every night, I’d gear up to make my rounds of rigorously scraping away all of that yucky green and purple film dust, and my cleaning cart would be loaded with noxious, highly toxic cleaning agents and exotic cleaning tools (*sarcasm*). No really, I’d grab my toothbrush, paint brush, Q-tips, and my spray bottle of isopropyl rubbing alcohol (yes, the kind used for scrapes and boo-boos).

I’ve since modified my tools just a bit to make them slightly more sewing machine friendly. Here is my current arsenal of tools.

- Isopropyl Rubbing Alcohol

- Assorted Small Paintbrushes (I have a round one and a “cheapy” kid’s brush)

- Any screwdrivers that came with your machine

- Cleaning Brush that came with your machine

- Tweezers

- Q-Tips

Let’s get to cleaning!

1. Make sure your machine is unplugged or turned OFF!! We don’t want any accidental trips to the ER.

2. Remove your Presser Foot.

3. Remove your needle. This may be a good time to discard that needle if it’s been awhile!

4. Remove your needle plate cover and needle plate (On my Brother SE-400, I have to first remove my Flat Bed attachment). You may have to unscrew a few screws to do this – put those screws in a SAFE place!

5. Now this is where the fun starts! Remove your bobbin and bobbin chamber. You can take the cleaning brush that came with your machine (or I like to use my round paint brush) and sweep out all of that fabric lint that collected in the bobbin chamber. Turn your thread-guide disk (the circular handle that raises your needle up and down) a half turn to make sure you don’t miss all the lint on the other side. Use your tweezers to snatch up any big, burly blobs of lint hanging around in there.

6. Remove any lint from the feed dogs. My machine likes to collect big chunks in between the dogs.

7. Take the long-handled “cheapy” paintbrush to brush out some of the hard-to-reach lint that’s fallen into your machine. I like the fact that the handle on this brush is so cheaply made that it actually bends. If you have a computerized sewing machine, PLEASE be careful around the cords!!! A light brushing is all you really need.

8. Armed with your Q-tips and alcohol, spray or dip your Q-tip into the alcohol. DO NOT SPRAY INTO YOUR MACHINE!!! The small amount of moisture will collect some of the more resilient lint remnants and get your machine all spruced up! If you happen to get your hands on some long-handled cotton swabs, they are awesome for cleaning some of the harder to reach spots inside your machine. (You can order HERE with free shipping). Lightly brush around all of the exposed metal surfaces in your bobbin chamber and surrounding areas. If you’re worried about using the alcohol on your sensors (like the Bobbin thread sensor), don’t be! Remember that super expensive film projector? This is exactly how we cleaned the sound-head sensor that read the audio strip on the film.

|

| Don't forget to clean around the Needle Bar Thread Guide!! |

(Fun Fact: That little green bar on the side of the film is what gives sound to your movie, or DID anyway…sigh!)

|

| My film Bow! You know I had to figure out SOMETHING cute to do with my film stash! |

9. Time to tackle my spool pin! I don’t know about you, but my spool pins really tend to gunk up from all of the sticky residue on my spools of thread. To clean it, I’m simply going to dip my Q-tip in alcohol and, “Make it shine like the top of the Chrysler building!” (Sorry, we’re BIG Annie fans in my house).

|

| Looks BRAND NEW!! |

10. Reassemble your bobbin chamber (on my machine I line up the little white dots), screw your needle plate back on, snap your needle plate cover into place, screw your foot pedal back on, and insert your brand-new needle.

TA-DA!! You now have a sparkling (almost new) sewing machine!

This is all of the gunk that came out of my machine today. I don’t know why, but cleaning my machine is oddly satisfying. :)

|

*Regular maintenance of your machine is EXTREMELY important and will help to keep those service calls to a minimum!

Now go sew something WONDERFUL!